The density of aluminum profile is only 2.7g/cm3, about 1 / 3 of that of steel, copper or brass (7.83g/cm3, 8.93g/cm3, respectively). In most environmental conditions, including air, water (or salt water), petrochemistry and many chemical systems, aluminum can show excellent corrosion resistance.

conductivity

Aluminum profile is often selected because of its excellent conductivity. On the basis of equal weight, the conductivity of aluminum is nearly twice that of copper.

Thermal conductivity

The thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchanger, evaporator, heating appliances, cooking utensils, as well as the cylinder head and radiator of automobile.

Non ferromagnetism

Aluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles can not self ignite, which is important for applications involving handling or contact with flammable and explosive materials.

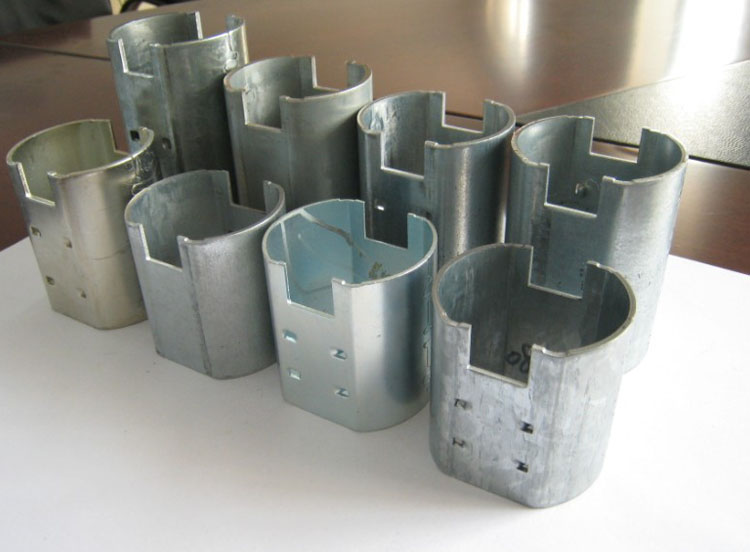

Machinability

The machinability of aluminum profile is excellent. In all kinds of deformed aluminum alloy and cast aluminum alloy, as well as in all kinds of states that these alloys have after they are produced, the change of machining characteristics is quite large, which requires special machine tools or technologies.

Formability

Specific tensile strength, yield strength, ductility and corresponding work hardening rate control the variation of allowable deformation.

Recyclability

Aluminum has a very high recovery, the characteristics of recycled aluminum and primary aluminum almost no difference.